Views: 0 Author: Site Editor Publish Time: 2025-12-26 Origin: Site

Substrate cultivation: Use soil-free media (coco coir, perlite) in the green inserts, paired with an automated drip irrigation system.

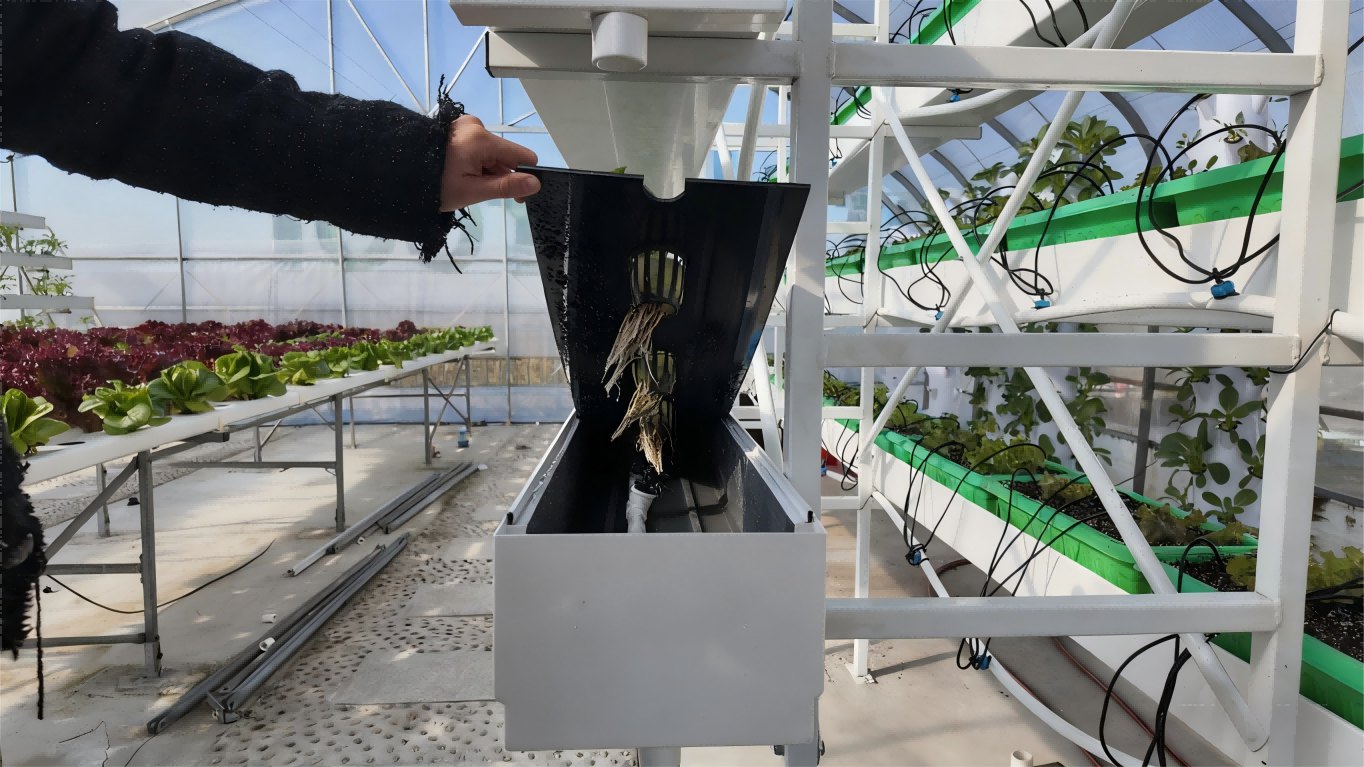

Aeroponic (hydroponic) cultivation: Remove the inserts to use the hollow trough as an aeroponic chamber—nutrient-rich mist is delivered directly to plant roots.

Dual-Function Compatibility: The trough’s hollow interior supports aeroponic mist circulation (for hydroponic crops), while its top rails secure substrate inserts (for drip-irrigated plants)—no need for separate planters for different cultivation methods.

Optimal Drainage & Ventilation: For substrate cultivation, the trough’s hollow base prevents waterlogging (excess moisture drains into the chamber, reducing root rot risk). For aeroponics, the enclosed space ensures nutrient mist is evenly distributed to roots.

Easy Cleaning & Maintenance: The trough’s smooth, detachable design simplifies sanitization between crop cycles—a critical detail for meeting EU/US food safety standards.

Space Efficiency: Multi-tier framing + dual-method troughs let you grow 2x more crop varieties in the same greenhouse footprint (e.g., lettuce via aeroponics and herbs via substrate cultivation, side-by-side).

How it works: Nutrient-rich water is atomized into mist, delivered directly to exposed roots via built-in nozzles (seen in the hollow trough chamber).

Benefits for overseas growers:

30–50% faster growth (roots absorb nutrients/moisture instantly)—ideal for fast-turnover crops (lettuce, spinach) in high-demand markets (EU, US).

70% less water usage than soil cultivation—critical for arid regions (Middle East, Australia).

Zero soil-borne diseases—cuts pesticide costs and meets organic certification requirements.

How it works: Green inserts (filled with coco coir/perlite) sit on the trough’s rails, with an automated drip system delivering precise water/nutrient doses.

Benefits for overseas growers:

Suits crops that prefer stable root media (tomatoes, peppers, herbs)—expands your product range beyond leafy greens.

Drip system reduces nutrient waste by 40%—lowering operational costs for large-scale farms.

Inserts are reusable and easy to replace—minimizes downtime between crop cycles.

Aeroponic mode: Lettuce, kale, spinach, microgreens (fast-turnover, high-volume crops).

Substrate mode: Cherry tomatoes, basil, mint, peppers (high-value, long-cycle crops).

Overseas use cases: European vertical farms (space efficiency), Middle Eastern greenhouses (water savings), North American organic farms (pesticide reduction).